SHAFT POWER METER TECHNOLOGY – STRAIN GAUGE vs MAGNETIC

- Home

- »

- SHAFT POWER METER TECHNOLOGY – STRAIN...

VEINLAND TORXmeter

Vessel Performance Optimization with the right Shaft Power Meter Technology

Various sensors are required to further optimize vessel performances and operations in order to save fuel, cut down emissions and reduce operation costs. Significant benefits can be observed by “buckling up” two magnetic belts on the shaft.

If you require any further information, feel free to contact us!STRAIN GAUGE vs MAGNETIC

WHICH ONE IS BETTER?

Traditional Strain Gauge System |

|---|

| Requires adhesive to glue the strain gauge |

| Requires electricity to rotate and measure |

| Requires professional experience and thus higher installation costs |

| Major issue 1: does not last in the long run, oily surface of the shaft |

| Major issue 2: During repair and maintenance of the shaft, the attached strain gauge has to be removed by skilled service technician and glued again after servicing. |

| VEINLAND TORXmeter with magnetic sensors (Made in Germany) |

|---|

| Utilizes magnetic coded EXFR belts |

| No electricity is required, hence no electronic parts |

| Simple and flexible installation |

| Tailor-made to fit the diameter of the intermediate shaft |

| Contact-free between sensors & the shaft |

| High accuracy |

| Each belt can easily be fixed using 2 small screws, no skilled service technician required |

| Calibration within several minutes |

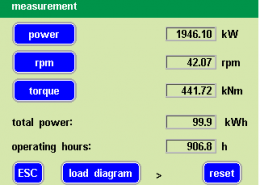

| Signals and readings can be saved on the device itself |

| NMEA and analogue outputs available |

Easy Installation – Light Maintenance

Contrary to traditional strain gauge systems, the magnetic belts can be fixed easily using 2 small screws on the shaft, hence no skilled technician required.

Neither adhesive nor glue has to be applied on the shaft, thus less hassle for future maintenance work.

Contact Free – German Technology

Made-in-Germany magnetic coded EXFR belts promotes easier calibration and zero contact is necessary between the magnetic sensors and the shaft, serving as one of the key indicators to evaluate EEXI.

New & Retrofit – Accurate Readings

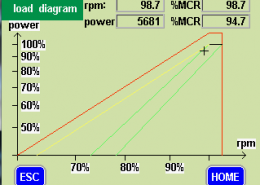

Suitable for all types of vessels, including new and retrofit projects, the shaft power meter provides accurate torque, shaft RPM and shaft power readings for tankers, bulk carriers, cargo ships, container ships, etc.

Precise – Multiple Outputs

Designed to fit the shaft diameter (tailor-made belts), the shaft power meter has multiple NMEA and analogue outputs available for various systems onboard, eg. (third-party) Vessel Performance Monitoring Veinland PIM OBU.